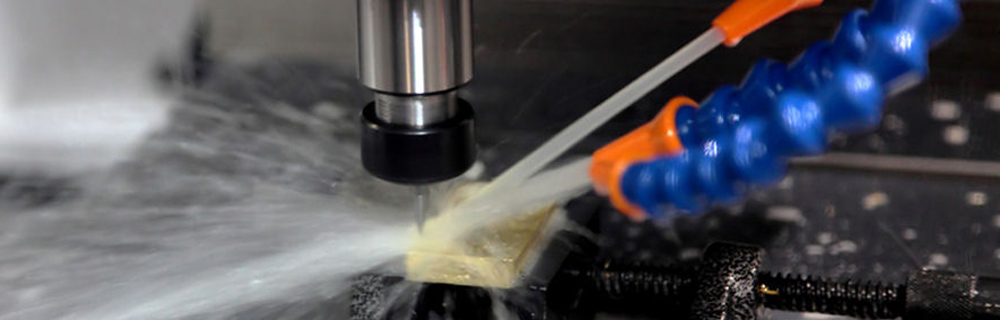

Glass Cutting

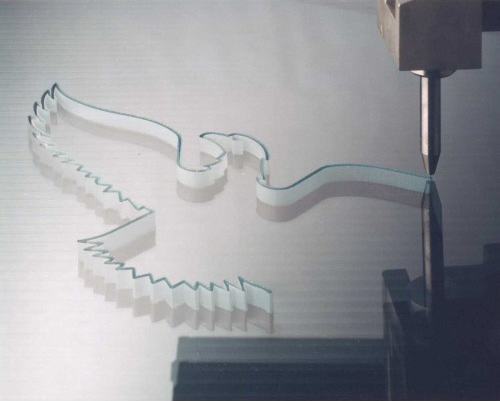

We hold expert domain in offering glass cutting services to our clients. Glass cutting is done with the help of a Water jet and at a reduced pressure of 500 to 800 bar, ensuring safety of the glass. In this process olive is preferred over quartz sand as an abrasive because olive is softer than quartz. Olive provides smooth finish to the glass and help in reducing the chances of cracking or chipping of the glass. Our high pressure pumps are widely used for varied applications as these have a maximum volumetric flow of more than 15 l/min and maximum cutting waterjet pressures of up to 6200 bar.

Advantages :

- Allows for complex and fine profiles that cannot be achieved with other methods at reasonable costs.

- Glass does not crack during processing.

- Suitable for the cutting of various glass types.

- Cuts glass panels up to 20 cm in thickness.

- No need to change tool when changing from thin glass to thick glass.

- No or reduced need for reworking of the cut edge.

- No wastage of material, narrow cutting gap.

- Efficient method to produce holes in glass.

- No need for re-sharpening the tool.

- Not suitable for the processing of hot glass.